How to balance TiO2 dispersion efficiency and pigment compatibility?┃Dispersant Solution:Coadd™ D-6739

Release time: 2026-02-05

Are you facing these dispersion challenges?

- TiO2 pigment concentrates prone to settling and water separation, with poor storage stability?

- Floating, flooding, or separation after tinting, with poor batch-to-batch consistency?

- Insufficient compatibility across different resin systems, leading to performance variability?

In coating production, pigment dispersion affects not only appearance, but also process stability, formulation reliability, and final coating performance. Instability at any stage may lead to batch-to-batch color variation, increased rework, and even customer complaints.

The real challenge is more than just dispersion

- Incomplete TiO2 dispersion

Incomplete TiO2 dispersion leads to reduced hiding power and whiteness, hard sediment during storage, and requires re-milling before use, causing production delays.

- Floating or separation after tinting

When using pigments such as phthalocyanine blue, iron oxides, and organic red or yellow, combining with TiO2 may cause color deviation, affecting tinting accuracy.

- Compatibility challenges when switching resin systems

In waterborne acrylics, 2KPU, epoxy, and amino baking systems, incompatibility of the same dispersant solution can cause performance variability.

- Poor storage stability

After heat storage, re-agglomeration, water separation, and viscosity changes can directly affect product performance and application.

True system solutions come from a deep understanding of complex systems

After extensive R&D and repeated testing, we developed Coadd™ D-6739, a multifunctional dispersant focused on efficient TiO₂ dispersion while broadly compatible with various pigments and resin systems. It addresses more than a single issue, providing stability for the entire color formulation system.

Key Performance of Coadd™ D-6739

- Excellent TiO₂dispersion

Maintains flow in 70% high-content TiO2 pigment concentrate after 14 days at 50 °C, with no hard sediment and only slight water separation.

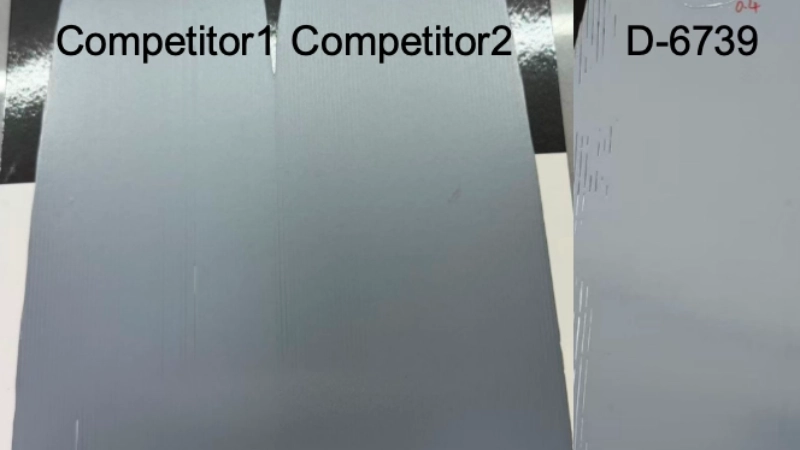

- Broad pigment compatibility

Works well with inorganic pigments (TiO₂, iron oxides, barium sulfate) and organic pigments (phthalocyanine, azo, etc.), effectively preventing floating caused by pigment competition during mixing or tinting.

- Cross-system stability

Significantly improves color consistency and storage stability across waterborne acrylic, 2KPU, epoxy, and amino baking systems.

- Synergy and formulation flexibility

Can be used together with other additives, offering solutions adapted to high-solvent systems, poor tinting stability, and re-agglomeration during heat storage.

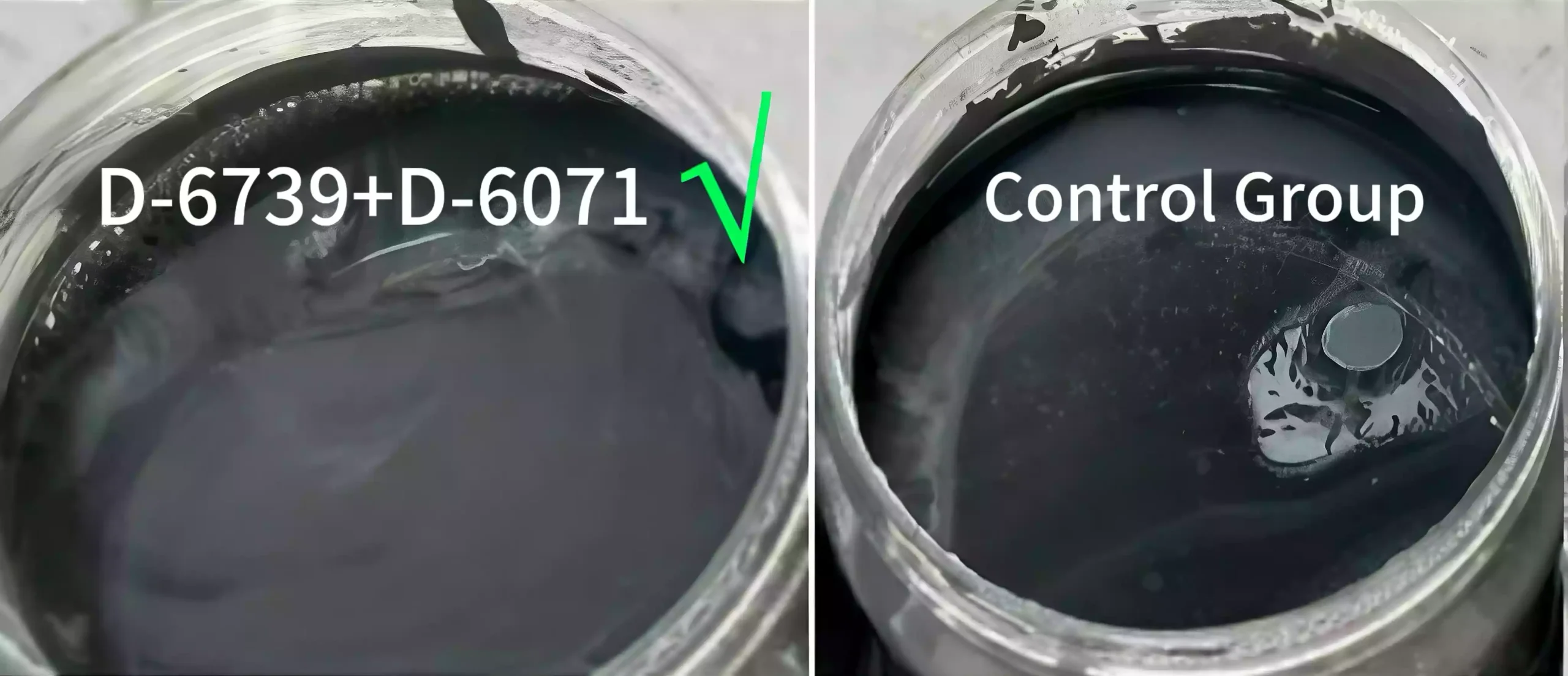

Coadd™ D-6739 + D-6071 Test in acrylic systems

(Anti-flocculation and re-coarsening under solvent shock and improved floating and flooding)

Coadd™ D-6739 + D-6071 Test in Amino Baking System

Recommended Systems for Coadd™ D-6739

- Waterborne inorganic pigment concentrates (TiO₂, BaSO₄, etc.)

- Waterborne acrylic systems

- Waterborne 2KPU

- Waterborne 2K epoxy

- Waterborne industrial coatings

Test in 2K Epoxy Systems

(Coadd™ D-6739 offers improved salt spray resistance.)

Coadd™ D-6739 provides a proven solution for dispersion and stability challenges in TiO2 and mixed pigment systems. It effectively improves grinding efficiency, ensures color consistency, enhances storage stability, and helps reduce production variability, supporting more robust formulations.

For more technical details, sample requests, or application testing, please contact us for support to help optimize your coating solutions.